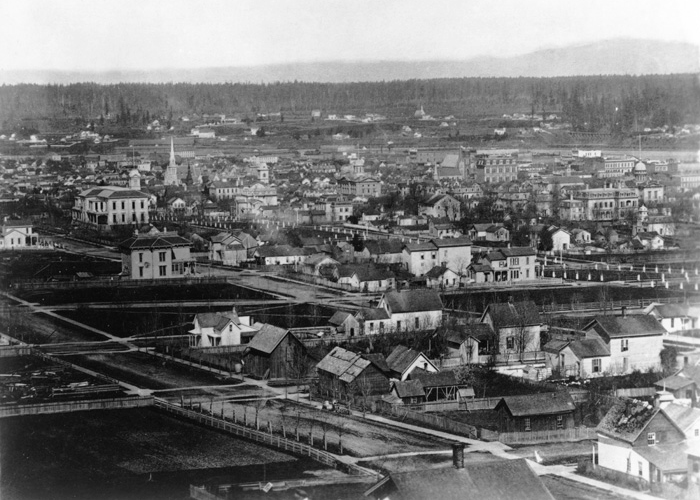

looking east...

looking east...

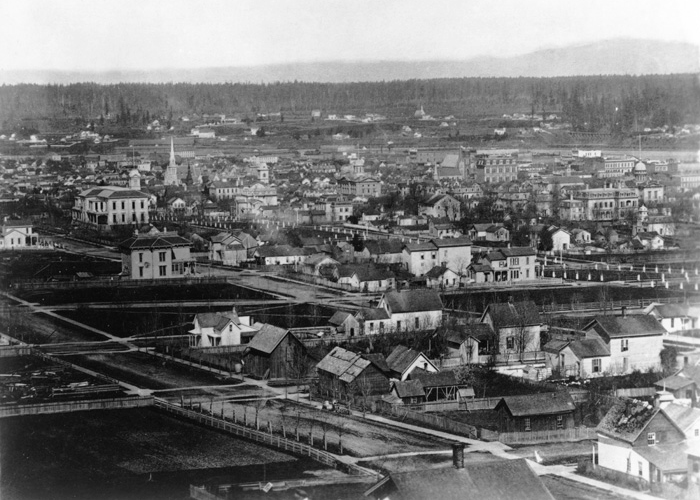

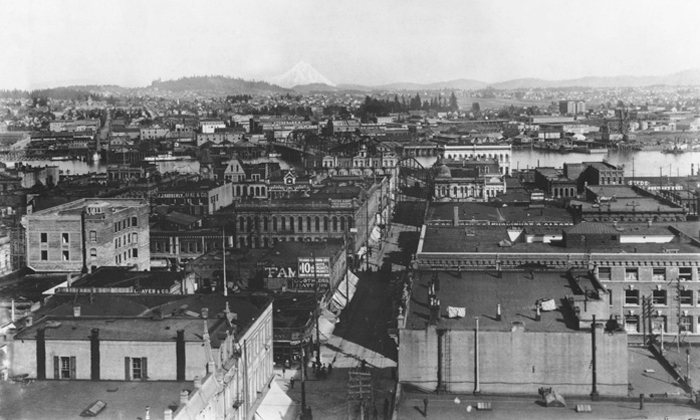

The image below, with Pioneer Courthouse in the center, gives a good sense of how the city has filled in during its first 30 years. Note, however, that the east side of the river remains relatively little developed. By 1878, when this picture was taken, Portland had a population of more than 10,000 and was already beginning to gain a reputation for the architectural quality of its homes and commercial establishments.

OrHi 8280

looking southeast...

looking southeast...

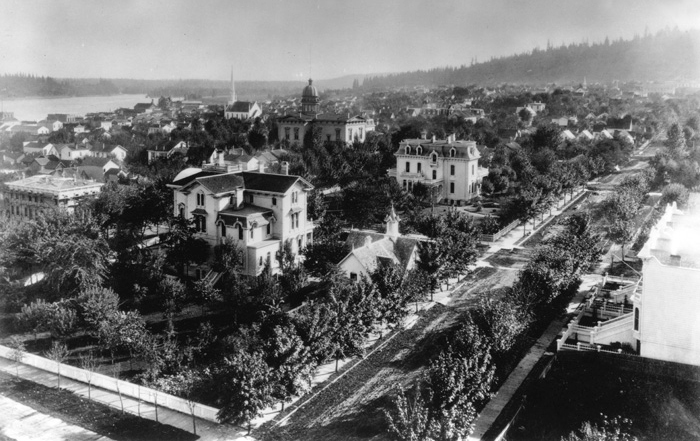

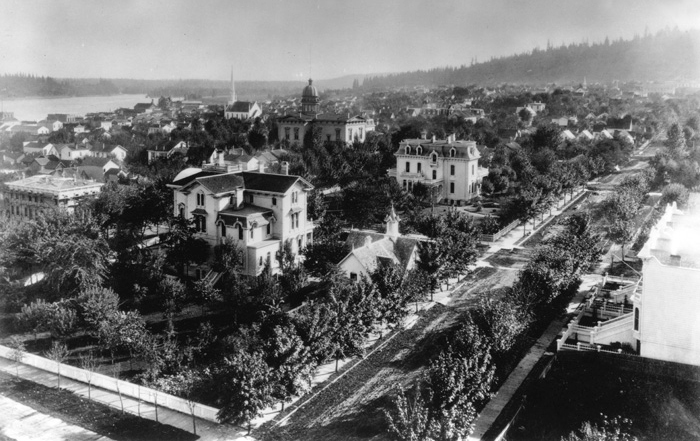

The 1878 view below is from atop Central School, just west of the courthouse (which is out of the photograph to the left). It looks southeast onto the Corbett Block immediately in the foreground.The Failing residence is just beyond. The domed Multnomah County Courthouse is in the near distance with Ross Island in the background. Note the plethora of trees and the handsome fences. How different that view is today! OrHi 759

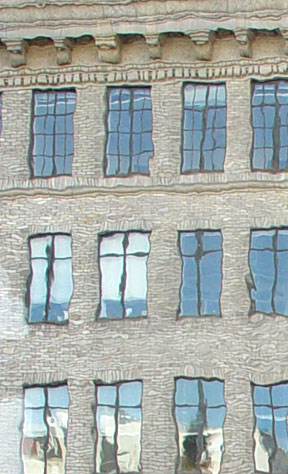

When you look out the windows in the cupola, they look wavy, curved, scratched, and “dimpled” almost as if they’ve “sagged” since their installation over 130 years ago.

When you look out the windows in the cupola, they look wavy, curved, scratched, and “dimpled” almost as if they’ve “sagged” since their installation over 130 years ago.

Stories are told of old windowpanes "flowing" under their own weight, becoming thicker at the bottom from having "sagged" over the years. Physicists and chemists now generally discount the idea that old window glass "flows," thus distorting its shape and clarity. Distortions and imperfections must find other explanations, because glass such as that used in windows such as the Pioneer Courthouse's is, in fact, a rigid solid. Laboratory analysis shows that glass should not deform significantly, even over many centuries. Clear links have now been found between deformations—waves, dimples, and, lines, such as those in the windows before you—and the manufacturing process.

So, how were old glass windows, like the ones in the cupola, produced? The process was an ancient one, going back 2,000 years to the Romans and continuing commercially until a century ago (and artistically today). Nine to ten pounds of molten glass was collected in a lump, rolled, and then blown into the shape of a flask, which was then expanded and flattened to the shape of an enormous decanter.The "decanter" was then reheated in a flashing furnace and whirled into a thin, transparent circular plate of glass. In this way a flat, circular disc, nearly sixty inches in diameter, was produced, of almost uniform thickness, except at the point of attachment in the center, where there was a swelling called the bull'seye. Centrifugal force thickened the outer rim of the glass "plate."

After the glass cooled, panes were cut into various shapes for windows.The cutting of a circle into rectangular sheets led to considerable waste. Uniformity of thickness, except by the most skillful manipulation, was difficult to attain.The splitter carefully examined each circle of glass before splitting it, and turned it around until he brought it into the position in which he could split it to the best advantage.The first quality was called best, the next, seconds, then thirds and fourths.

The thicker edges were customarily placed at the bottom when mounted in a window frame (hence the observation that old windows are thicker at the bottom). The glass was amazingly flat and uniform in thickness for a handfabricated disk five feet in diameter (but not in comparison to sheet glass drawing processes of recent years and float glass processes widely used now).

The variations in thickness were apparently of less concern than other deformations such as waves, blisters, dust, lines, curves, and scratches. Such "defects," as we see in some of the windows here in the cupola, were common and accepted by glazers, architects, and their clients, like the federal government in the Pioneer Courthouse's case.

looking east...

looking east...

Climb the stairs up from the courthouse attic to visit the cupola to see those views, as well as photos of what Portland looked like more than a century ago in every direction. Here are a few samples...

Climb the stairs up from the courthouse attic to visit the cupola to see those views, as well as photos of what Portland looked like more than a century ago in every direction. Here are a few samples...

looking southeast...

looking southeast...

When you look out the windows in the cupola, they look wavy, curved, scratched, and “dimpled” almost as if they’ve “sagged” since their installation over 130 years ago.

When you look out the windows in the cupola, they look wavy, curved, scratched, and “dimpled” almost as if they’ve “sagged” since their installation over 130 years ago.